HAUS Natural Cork flooring system is designed for use as non-structural overlay flooring inside residential and commercial buildings.

1 SCOPE OF USE

HAUS Natural Cork flooring system is designed for use as non-structural overlay flooring inside

residential and commercial buildings. Installations outside of the scope of use will not be covered

under warranty.

• Our flooring is suitable for all areas other than garages and commercial kitchens.

• Our flooring should always be installed onto an approved substrate.

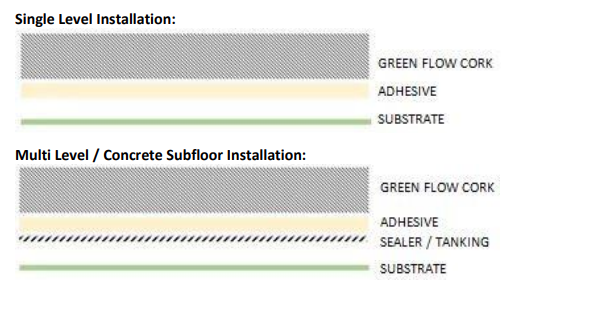

• Additional requirements must be adhered to for installations in wet areas in multi-level dwellings in regard to water containment.

• Additional requirements must be adhered to for installations with underfloor heating.

2 APPROVED SUBSTRATES

1) Concrete floors

2) Timber flooring (structural or overlay)

3) Concrete floors with hydronic underfloor heating systems

4) In-screed electric underfloor heating system

5) Wet-area membrane systems (when approved by the membrane system supplier)

6) Acoustic underlay glued to an approved substrate

3 SLIP RESISTANCE

In regards to slip resistance, please check the recommendations from your local Council. Particularly for commercial applications.

Entrance mats should always be incorporated at main entrance points, especially in commercial

settings, to minimize damage.

4 WET AREAS

A wet area is a kitchen, bathroom, laundry, toilet and any other area containing sanitary

fixtures/appliances.

Under changes to E3/AS1 from 4/11/2021 ‘Acceptable Solutions’ in wet areas are

only; Tiles, Vinyl or Polished Concrete. Cork flooring in wet areas must now be submitted to Council under the category ‘Alternative Solution’. Cork flooring is an acceptable alternative solution for wet areas.

5 INSTALLATION GUIDE FOR HAUS NATURAL CORK FLOORING PRE-FINISHED

CLICK LOCK CORK

Cork is to be glued down (not floated) and glue must be trowelled.

6 FINISHES (COATING)

High-Performance Super HRF Finish – high resistance finish made up of nano-ceramic particles.

7 CLEANING & MAINTENANCE

-Keep your floors free of dirt, grit, and abrasive particles.

-Use electrostatic mats and mops where ever possible to greatly reduce the need for maintenance.

-Avoid dragging furniture and appliances over the surface. Protective pads should be used on the legs of furniture.

-Sweep or vacuum to remove dust and grit particles. Do not use floor polish or other maintenance

dressings and ensure that your mop head is clear of all previous polishes.

-Do not use abrasive cleaners. Wash the floor regularly with hot water and small amount of dishwashing detergent.

-Do not use scrubbing machines.

-Use Bona Cleaner for spot cleaning as required – for black rubber or shoe marks rub with a dry cloth.

-Regularly mop your floor with Bona Cleaner and a micro fibre spray mop. Allow the floor to dry completely before walking on it.

-Do not use steam mops.

8 UNDERFLOOR HEATING GUIDELINES

Cork is an insulator and inherently a warm product - underfloor heating may not be needed.

HAUS Natural Cork Flooring glue down cork products can be installed over in-slab waterborne under-floor heating as long

as the following instructions are observed:

-The temperature of the subfloor must not exceed 26°C (78.8°F). For detailed information, follow the instructions supplied by the subfloor heating system manufacturer/contractor, or contact your supplier.

-Remember that rugs or mats placed on top of the floor may function as heat accumulators and will increase the floor surface temperature more than the maximum surface temperature recommended (must not exceed 20 - 22 ºC).

-Any heated subfloor has certain working conditions depending on the heating system and the subfloor.

-In order to avoid problems with functioning and durability during the construction phase, the norms and

rules concerning installation are to be followed very strictly.

-The drying of a heated subfloor has to be made by turning the heating on/off with a pause before installation of the floor, following a documented protocol. After that, you can begin the “heating phase”.

-The beginning of the heating phase in concrete subfloors is to be made not before 21 days after the complete curing of the substrate. The heating phase has to begin with a running temperature of 25ºC (78ºF) during 3 days.

-The subfloor should be in place and cured for at least 60-90 days.

-The temperature should then be increased each day until the maximum temperature allowed according to the manufacturer’s system. This maximum value should be kept for at least 72 hours and maintained for 5-7 days without any turning off. The decrease of temperature is made by reducing it gradually every day until 18ºC on the surface is achieved.

-During the installation, the temperature of the surface should not exceed 18ºC (65ºF) and should be kept for 3 days after finishing the installation (for floating floors). Then the temperature should be increased slowly to a max. of 26°C (78.8°F) on the subfloor surface.