Asbestos in flooring can be found in older vinyl backings, vinyl tiles or old adhesives.

The era of assuming asbestos in buildings or refurbishments is prior 1 January 2000 (Duty 19 of the Health and Safety at Work (Asbestos) regulations 2016). While the asbestos is bonded throughout the floorcoverings (Non Friable) it is in a safe state. When broken, or the vinyl wear layer is separated from the backing exposing the fibres it is in an unsafe state (Friable).

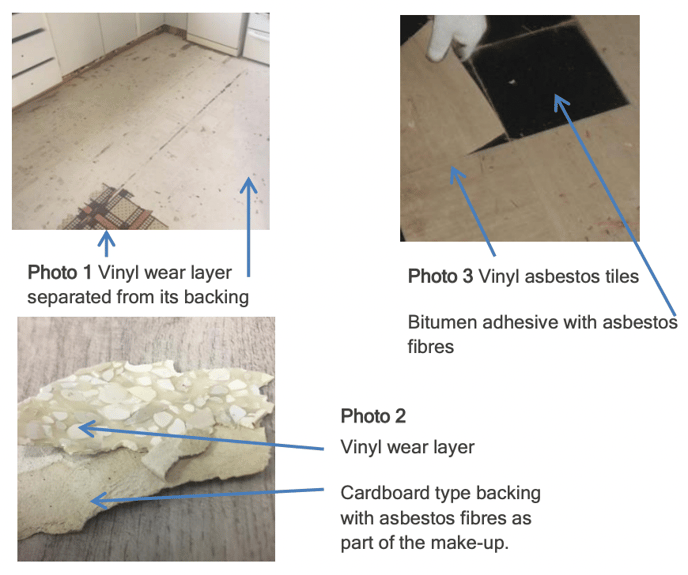

Photo 1 the area and tools used could be now contaminated with asbestos fibres. This situation requires the immediate advice and services of an accredited asbestos-specialist.

Photo 2 is a close-up view of an asbestos-backed vinyl.

Photo 3 is vinyl tile that has asbestos as part of the whole tile.

See Worksafe Issues Inspectors Find on site presentation:

https://www.youtube.com/watch?v=G4XvNPPzdQY

For further information on Asbestos visit:

https://worksafe.govt.nz/topic-and-industry/asbestos/

https://worksafe.govt.nz/topic-and-industry/asbestos/management-and-removal-of-asbestos/

DUTY TO PREPARE AN ASBESTOS MANAGEMENT PLAN (AM)

Due to previous floorcoverings installed containing asbestos, flooring businesses are required to have an Asbestos Management Plan (AMP) in the workplace (Duty 13 of the Health and Safety at Work (Asbestos) regulations 2016).

An Asbestos Management Plan sets out where any suspected asbestos or Asbestos containing Material (ACM) is, plus the next steps to take (Duty 10). Even if a flooring company that has no intended involvement with removing or encapsulating floorcoverings, an asbestos management plan is still needed to cover situations of providing advice to customers plus flooring contractors/workers that discover asbestos flooring materials hidden beneath floor covings (Duty 26). It is advisable to use the assistance of an accredited asbestos professional to develop an AMP that complies with the Asbestos regulations.

DUTY TO ENSURE ASBESTOS IS IDENTIFIED IN THE WORKPLACE

As part of the plan, a flooring business must provide training in asbestos awareness for their staff that provide flooring advice to potential customers, visit homes or buildings as part of their flooring work (Duty 10, Duty 17, Duty 25). It is not recommended by Worksafe or the Ministry of Health that a home owner/occupier removes asbestos containing flooring material. While home owner/occupier is not legislated by the Health and Safety at Work Act, there is a risk to:

- their own health;

- others in the house; also

- the flooring people who will be preparing the surface or installing the new floorcoverings.

The clean-up of a house that is contaminated with asbestos fibres is extremely expensive as all contaminated soft furnishings may need to be replaced. Advice to the customer should be to engage the services of a specialist in asbestos testing.

DUTY TO CARRY OUT AIR MONITORING

Any work involving the removing of friable asbestos needs the services of a Class A licenced operator (Duty 27). On completion a clearance inspection is required by an independent asbestos assessor, who will supply a clearance certificate (Duty 41). A clearance certificate that validates an asbestos removal activity can only be issued by a licenced assessor to a licenced removal contractor.

No future flooring work should start until the flooring company has been supplied with a copy of the clearance certificate (Duty 42).

For a private homeowner that has chosen to the asbestos themselves, (not recommended) the private homeowner will need to provide evidence that an area is free of asbestos materials or airborne contamination. They will need to engage the services of an asbestos consultant/surveyor or accredited laboratory to produce a survey/inspection report. The asbestos consultant will be able to visually identify any materials still present in an area/premise and also undertake air monitoring to quantify the level of any airborne asbestos fibres.

The inspection report will not relate to any historical activities that have occurred, the report will simply be stating any observed materials or contamination on the day of the inspection.

Flooring businesses (Person conducting a business or undertaking—PCBU) must ensure, so far as is reasonably practicable, that the health and safety of their workers or contractors are not put at risk from work carried out as part of the conduct of the business or undertaking (Duty 36 Health and Safety at Work Act 2015).

Confirming that any asbestos is present can only be identified by an accredited asbestos laboratory (Duty 11). Using any other means of testing is subject to a fine up to $10,000.

ENCAPSULATING ASBESTOS BACKED FLOOR COVERINGS

For situations where it is not feasible or is difficult to remove the asbestos backed floor coverings, a procedure will need to be devised and included as part of the flooring companies Asbestos Management Plan. The procedure will need to comply with the Asbestos regulations. This will include identifying if the work is demolition, refurbishment or maintenance.

While Duty27 (2,3) makes provision for unlicensed work as Minor contamination, the criteria of trained by a ‘Competent person’ applies and follows the Worksafe ‘Approved Management and Removal Code of Practice’.

Examples that need a procedure as part of the Asbestos Management Plan.

Encapsulation —a timber substrate where the option is taken to overlay an asbestos contained vinyl floorcovering with board underlay.

Because the asbestos will remain in place beneath the new floorcoverings, a warning notice for people doing future flooring work is also recommended. This can be:- placed on the existing floor covering; or

- a warning written in pencil on the board underlay. Pen or ink should not be used as it may show through a new vinyl floor covering at a later stage.

Sealing—where carpet is to be replaced or refitted over a suspected asbestos-backed floor covering and an installer finds an exposed damaged edge/doorway of the asbestos-backed vinyl. Asbestoscontaminated Dust or Debris (ACD) procedures should be put into place (from the Asbestos Management Plan) if sealing with an appropriate liquid is a feasible safe option for providing a protective coating to an exposed edge (Duty 27 (3) along with Duty 17).

Applying a cementitious compound as an underlayment over an exposed asbestos backing is not a safe option. This will disguise the problem and endanger any people that are involved with the future uplift or grinding of the cementitious surface.